The Difference Between H-Beams and I-Beams

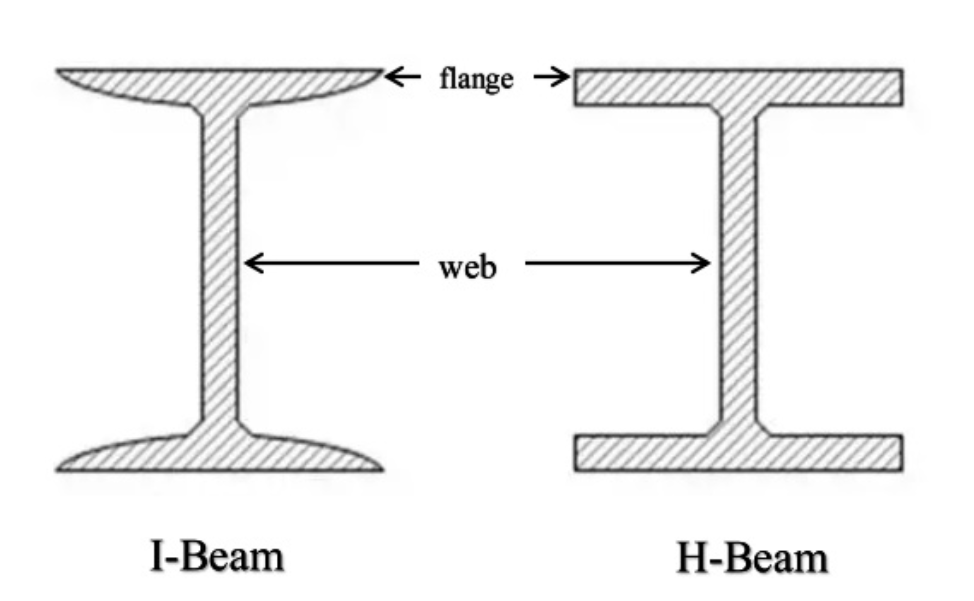

Many people often wonder, since I-beams and H-beams appear similar in appearance, what exactly are the differences between them? In reality, many people aren't entirely clear on this point. It's important to note that some believe "I-beam" is a Chinese term, while "H-beam" is a foreign term. This is inaccurate. In fact, the two have distinct cross-sectional shapes, as detailed below:

I-Beams

As the name suggests, I-beams are a type of steel with an "I"-shaped cross-section. The inner surfaces of their upper and lower flanges have a slope, typically 1:6, resulting in a thin outer flange and thick inner flange structure. Consequently, the cross-sectional properties of I-beams vary significantly along their two principal axes, making it difficult to fully utilize the material's strength properties in practical applications. Although thickened I-beams are available on the market, their structural characteristics result in insufficient torsional resistance.

H-Beams

H-beams are widely used in steel structures today and offer several significant advantages over I-beams. First, its wider flanges and parallel inner and outer surfaces make H-beams significantly superior to traditional I-beams, channels, and angles in cross-sectional performance.

H-beams derive their name from their cross-sectional shape, which resembles the letter "H." They offer an economical, high-performance steel cross-section with optimized cross-sectional distribution and a more favorable strength-to-weight ratio. Because their outer and inner edges are straight, H-beams are easier to weld and splice than I-beams, offering superior mechanical properties and saving significant material and labor.

Differences in Load-Bearing Properties Between I-Beams and H-Beams

Both standard and lightweight I-beams exhibit significantly different moments of inertia about their two principal axes due to their relatively tall and narrow cross-sectional dimensions. Therefore, I-beams are generally only suitable for components primarily subjected to in-plane bending within the web, or for forming lattice-type load-bearing components. Their use is significantly limited in axially compressed components or components subject to bending perpendicular to the web.

In contrast, H-beams are a highly efficient and economical cross-section with a comprehensive range of specifications and models, making them easy to choose from. Their widened flanges and parallel inner and outer surfaces make them more suitable for connecting with other components using high-strength bolts. Although the production process and equipment for H-beams are more complex than those of conventional rolling mills, their load-bearing capacity is significantly higher.

According to the Chinese National Standard for Hot-Rolled H-Beams (GB/T11263-1998), H-beams can be divided into three categories: narrow-flange (HZ), wide-flange (HK), and pile (HU). Narrow-flange H-beams are suitable for beams or compression-bending members, while wide-flange H-beams and H-piles are suitable for axially compressed or compression-bending members. Under conditions of equal weight, H-beams exhibit superior cross-sectional performance parameters (such as section modulus W, moment of inertia Ix, Iy) to I-beams.

In summary, despite their similar appearance, I-beams and H-beams differ significantly in their structural characteristics and application ranges. With its optimized cross-sectional shape and better mechanical properties, H-shaped steel has gradually become the mainstream profile in steel structure buildings.